Printing

Find out more about our industry leading large format printers as well as our roll printer capabilities enabling us to produce the vibrant, eye catching solutions you require.

Why Choose UV Printing?

UV printing allows us to offer vibrant , full colour applications on a wide range of rigid and flexible materials. The instant curing process ensures precise detail, durability, and a professional finish. All of this is achievable without smudging or needing drying time. It’s ideal for signage, branded products, labels, and intricate designs where being eye catching and precise is important. UV printing is the go to for vivid, dynamic and creative applications.

Our Printer Systems

We implement a wide range of printing applications into our trade solutions; from small stickers to full size hoarding boards, our printers can do it all.

Large Format Flatbed Printers

Used for flat, rigid substrates on a large scale.

Corex

ACM

Foamboard

Flatbed printers are used for .

Our flatbed printers are an essential part of our machinery allowing us to expand our what we can offer limitlessly. With full range CMYK colour as well as white, primer and clear capabilities, our large format printers are perfect for producing vibrant, full-colour designs, printing directly onto rigid materials like acrylic, wood, metal, and more. It offers precise detail, excellent durability, and instant curing — with no drying time needed. Ideal for signage, branded panels, plaques, and custom displays, it supports both short runs and one-off pieces.

Printing Area

Our largest flat bed printer spans 2.6 meters wide with over 3 meters of depth, giving us huge capabilities of large scale prints, efficiently producing batch orders and much more.

Registration Marks

To produce batch orders even more efficiently, we employ the Print and Cut method. This allows us to seamlessly print batch artwork with registration marks, then cut the each item with tight tolerances, saving time on printing items individually.

White, Clear & Primer

As well as the option of printing with full range CMYK colour, we have the capability to print white, clear varnish, and even primer. This eliminates the need for common pre-production and post-production, further improving our turn around times.

Vacuum Suction Table

The beds of our large format printers each house a powerful vacuum, securing materials firmly during printing. This helps to ensure accuracy, minimise variation in print, and eliminates the risk of substrates warping, lifting, or becoming uneven. The vacuum is split into controllable zones allowing us to precisely manage the suction for any job as necessary.

Laminating Capabilities

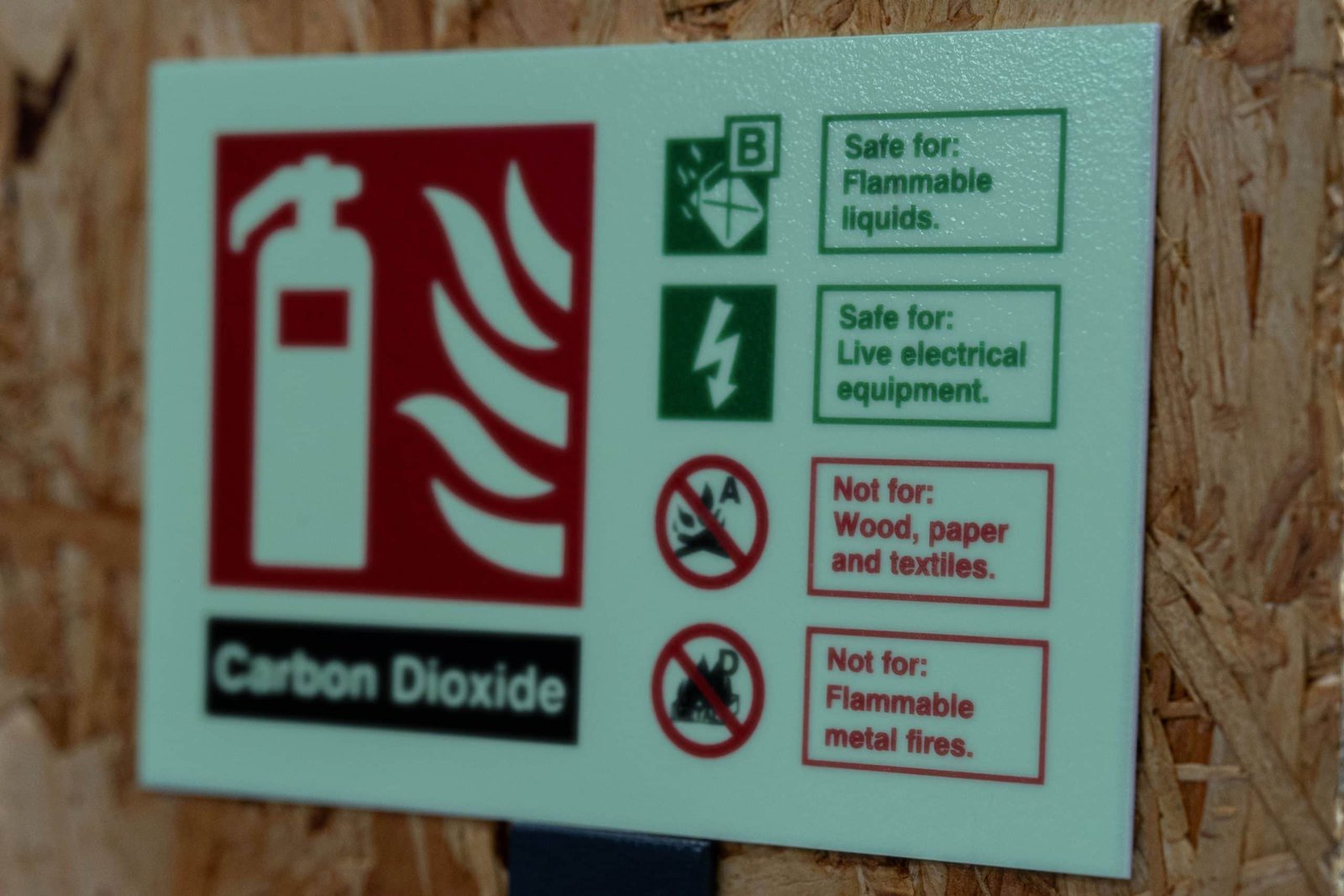

A piece of equipment we use in close conjunction with our printers is our laminating roller table. This allows us to take substrates to the next level with post production processes like clear lamination, pre-production processes such as photoluminescent (glow in the dark) vinyl, and much more.

Ideal for Custom Branding

We can print to foam, card, and a plethora of other substrates for displays and advertising, as well as corporate gifts and trophies — perfect to highlight your business with branded packaging or promotional material.

Roll to Roll Printers

Used for long and thin substrates like vinyl with printing and cutting capabilities.

Vinyl

Paper

Canvas

Vehicle Wrap

Roll printers are used for .

Roll to roll UV printing is ideal for high quality, full colour prints on flexible materials such as vinyl, banner media, and other film like substrates. It’s the perfect method for producing long and flexible graphics graphics, vehicle wraps, window films, and stickers with high detail and vibrant colour. The UV inks cure instantly, resulting in smudge free and weather resistant finishes suitable for indoor or outdoor use. This method supports both short runs and continuous production.

Printing Area

Our largest width of Roll to Roll printer is 1400mm. This specific form of printer takes rolls of material and feeds them through the machine meaning that the length of the print is purely limited by the material length – perfect for large banners or long spans of vinyl.

Built in Cutting

These printers differ from flatbeds as they house a versatile cutter as well as the printing heads. This eliminates the need for using multiple machines as the Roll printer can print meters of media and cut it to shape and size in the very same job, increasing production speeds immensely.

Roll to Roll

Roll to Roll is exactly what the name suggests; a material or substrate is passed through the printer allowing it to print as it is pulled through. It is then re-rolled onto an empty roll readily collectable or for easy packaging making the production of large flat graphics as efficient as possible.

Lamination Table Application

Using our lamination roll table, we can apply vinyl stickers or any other applicable print straight to any other rigid substrate. If there is a specific material you would like a vinyl print applied to, we will try our best to accommodate.

Long Banners

Due to the length of print having no limit, we are able to print long continuous artwork without having to stop and load more material. This is especially useful for long banners or anything else that would otherwise be limited by length, giving roll to roll the upper hand over flatbed for this application.

Scoring, Weeding & Cutting

The built in knife allows for us to print your desired artwork, score it to your desired shape and cut them separately – perfect for vinyl stickers, vehicle wrap and more. If necessary we also have the means to weed the cuts and apply masking tape for signwriting with our laminating table.

UV Printer Capabilities

See our most commonly produced products and services offered with our UV printers.

Site Signage

Hoarding Boards

Vinyl Labels

Clear and Photoluminescent Laminating

Branding and Business Signage

Wayfinding Signage

Ready to Start Your Project?

Trade Engraving Printing Routing Cutting

We offer a comprehensive range of engraving and printing services tailored to meet your specific requirements.